Prominent position in the New England Orogen

Doherty and Basin Manganese Project

Located 100km north of Tamworth in northern New South Wales, Great Dirt’s Doherty and Basin Projects comprises 168km2 within license EL9527. The Project is prospective for high grade manganese, with both projects producing metallurgical and battery grade manganese historically.

Great Dirt’s Doherty and Basin Project includes the historic Doherty and Junior Mines to the south, and Basin Farm and Girraween workings to the north, along with numerous manganese workings within the license.

At a glance

- A proven region for high grade manganese, that has supplied battery manufacturers from the 1940s-1960s.

- Floaters of high-grade ore reported outside of known mine areas are a direct indication of unidentified manganese mineralisation.

- Technology Modern, systemic, geochemical and geophysical exploration techniques employed to locate near surface, high-grade, manganese mineralisation.

- Discovery of Massive Manganese Mineralisation up to 50.3%.

- Successfully completed maiden drill program with high grade intersections, including single metre intervals of 36.10% and 33.20% Mn.

Doherty Project

The Doherty Project is located in the southeastern section of EL9527. The area comprises of the historic Doherty and Junior Mines, Neranghi and Dailey’s deposit.

Doherty Mine – Open cut and underground operations extend for >300m, majority of 6000t production was battery grade manganese ore supplied to Eveready, shipment grades reported in mines inspection report battery grade (74.3%) and metallurgical grade (46%) manganese.

Junior Mine – Produced 3,000 tonnes of mostly metallurgical grade manganese ore, supplied to BHP for steel production, saddle shaped lenses worked for more than 60m, abundant ore remains, lowering grade and failing market force closure, ore assayed 29% Mn.

Neranghi – Shallow workings on parallel lenses of massive ore, multiple pits 25m wide, ore assayed at 50% Mn, numerous deposits to the south with potential for further progression.

Daileys Deposit – Shallow workings on several ore lenses with clay, abundant ore remains insitu, ore assayed 31% Mn.

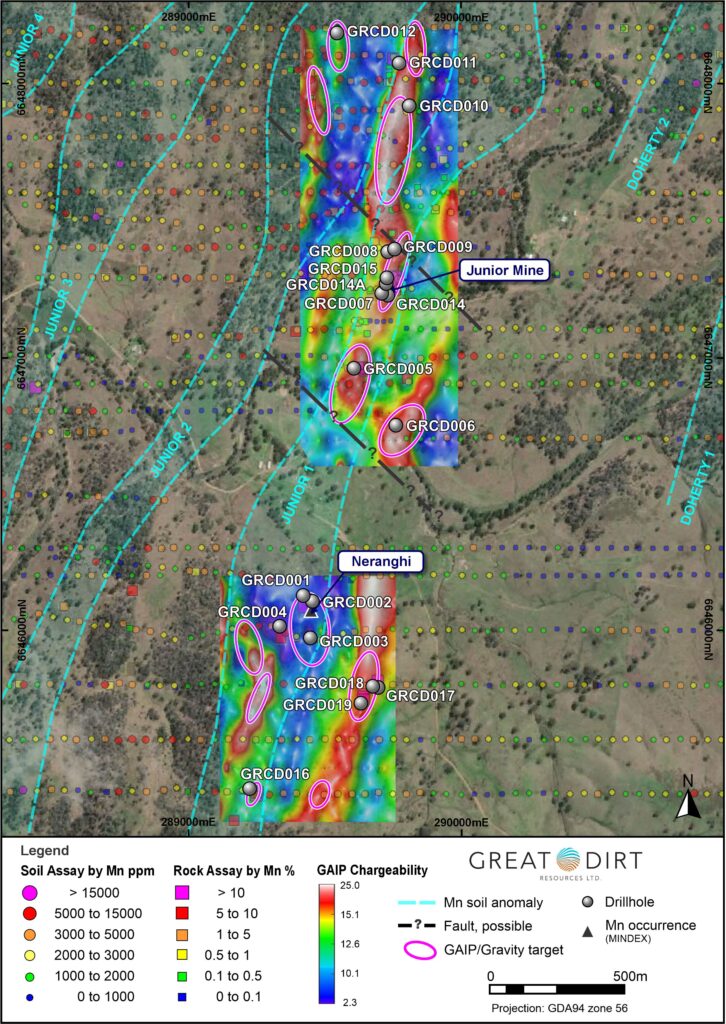

Recent soil and rock chip sampling results indicates the extension of the Junior targets to the north, with mineralisation in the south consistent with the southern boundary of EL9527. Ground based GAIP and Gravity geophysical surveys define significant, large scale, linear features, coincident to Mn in soil anomalism. Field investigation of geophysical targets led to the discovery of massive manganese mineralisation south of Neranghi with samples assaying up to 50.3% Mn.

Multiple drill targets have been define, with drilling scheduled for later half of the year.

In late 2025, Great Dirt successfully completed its maiden drilling campaign, comprising 19 holes for a total of 1,701m. Results from ALS Laboratory Brisbane confirm extensive manganese mineralisation, bolstering the prospect’s potential.

Drilling at the Junior Prospect has successfully mapped manganese mineralisation over 2,000 metres of strike from northeast to southwest (GRCD015 – GRCD016). Additionally, several holes intersected multiple lodes, substantially increasing the project’s future tonnage potential.

Major intercepts include:

- GRCD015 – 21.30% Mn over 5m from 22m downhole including 4m at 23.96% Mn, 2m at 29.65% Mn and 1m at 36.10% Mn.

- GRCD007 – 18.74% Mn over 3m from 25m downhole including 2m at 24.98% Mn and 1m at 33.20% Mn. GRCD-007 provides further evidence of numerous lodes of manganese mineralisation occurring within the project area adding to the potential size of the Junior Prospect.

- GRCD014 – 9.07% Mn over 4m from 23m downhole including 1m at 10.45% Mn.

Basin Project

The Basin Project is located in the Northwestern section of EL9527. The area comprises of multiple historical workings including Girraween and Basin Farm.

Preliminary investigations of manganese occurrences, including some small workings, and other obvious elongate magnetic features has led to the discovery of massive manganese mineralisation at the Basin Project with samples assaying up to 54.5% Mn (GRR272).

Girraween comprises a group of two different workings.

Girraween (150081) is described as scattered pits on numerous lenses over a length of 37m and width of 15m, individual lenses up to 4m wide of stratiform to massive manganese of submarine volcanic origin.

Girraween (150082) is described as shallow pits 2m wide exploiting massive psilomelane, abundant mineralisation in outcrop between the pits over more than 35m, lenses outcrop on ridges to the north and south. The 5 rock chip samples that were taken from various locations at the Girraween occurrences returned between 45.1% and 52.4% Mn (GRR276-280).

Basin Farm workings comprised some small pits 2m wide and remnant stockpiled manganese oxide adjacent to the workings, manganese likely of submarine volcanic origin. Of most interest is GRR272, located midway between Basin Farm and Girraween, returned the best result with 54.5% Mn. This area and extents to Basin Farm and Girraween will be tested.